|

范文编号:JX021 包括设计范文和设计图纸,字数:19834,页数:59.

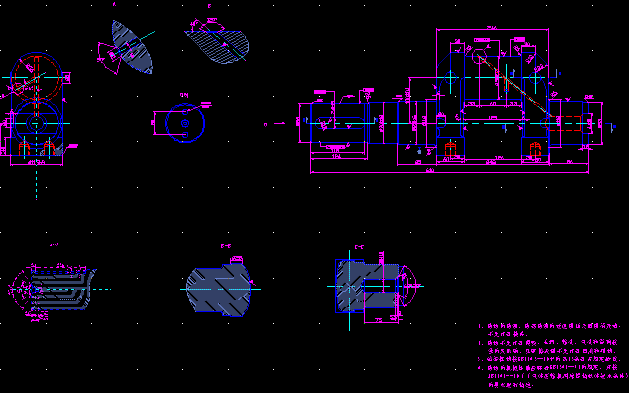

摘 要 此次文档设计任务是对3L-10/8空气压缩机曲轴零件的机械加工工艺、夹具的设计,在曲轴零件的加工工艺过程中轴与轴中心线之间要有位置要求, 以毛坯轴两端定位先加工两中心孔,以两端中心孔定位再粗、精加工各轴的表面,然后以粗、精后的两轴径定位钻螺纹、铣键槽和铣曲拐端面,采用专用夹具加工两斜油孔,最后粗、精磨各轴。

ABSTRACT This graduation project duty is to the 3L-10/8 air compressor crank components machine-finishing craft, the jig design, between the crank components processing technological process middle axle and the axle must have the position request ,processes two center bores first by the semifinished materials axis both sides localization ,by both sides center bore localization again thick, precision work various axes surface.Then after thick, the essence two axle diameter localization drills the thread, the keyseat and the mill crank end surface.,uses the unit clamp to process two slanting oil holes, finally thick, correct grinding various axes.

目 录 摘 要 ...................................................................I

|

| 上一篇:CA6140机床后托架加工工艺及夹具.. | 下一篇:数控激光切割机设计 机电一体化 |

| 点击查看关于 空气压缩机 曲轴零件 机械加工 工艺及夹具设计 的相关范文题目 | 【返回顶部】 |