|

范文编号:JX731 范文字数:13850.页数:33 附CAD图

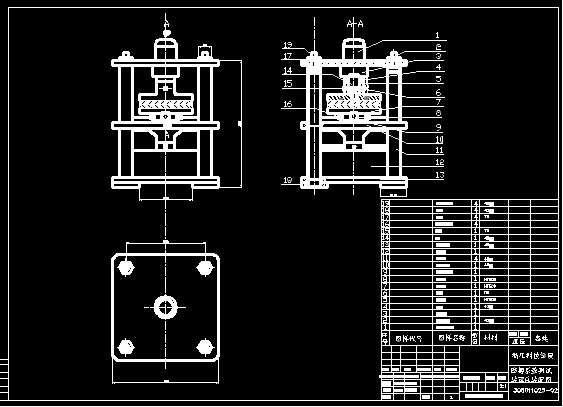

摘 要 摩擦、磨损和润滑在机械设计中占有重要的地位,特别是现代机械产品在向高速、高精度大批量和生产过程高度自动化、连续化的方向发展过程中,机械设计,如果不考虑摩擦、磨损和润滑问题,就不可能设计出符合要求的好的机械产品。也就是说,对于现代的机械产品,在其设计阶段就应该把控制摩擦和防止磨损的一切因素都尽量考虑进去,并应用摩擦和磨损的有关理论知识和抗磨技术去指导设计、制造、运行和维修,以解决机械设计中的有关问题。摩擦系数工作在滑动摩擦状态下质量特性的关键性指标。针对测试环境要求,研究设计了一种新型摩擦系数高精度测试仪。讨论了摩擦系数测试的原理与方法,设计了摩擦系数测试台的基本结构,研究了力传感器的工程实现步骤。整个测试仪的综合测试准确度优于5%。 The Design and Implementation of Ring Coefficient of Friction Tester Friction, wear and lubrication play an important role in mechanical design, especially in modern machinery to high-speed, high-precision,high-volume and highly automated production process, direction of continuous development. In mechanical design, if you do not consider the friction , wear and lubrication problems. We can not design good mechanical products which meet the requirements of good mechanical products. That is, for modern machinery, in its design phase should be controlled to prevent friction and wear as much as possible all the factors should be taken into account, and apply the friction and wear of the theoretical knowledge and the wear technology to guide the design, manufacture, operation and maintenance, to address issues related to machine design. The key indicators of quality characteristics for coefficient of friction that work in the sliding friction.

摘要……………………………………………………………………………………ⅰ 环式摩擦系数测试装置设计相关范文 |

| 上一篇:基于UG的锥差式减速器设计 | 下一篇:荷载箱的设计 |

| 点击查看关于 摩擦 系数 测试 装置 设计 的相关范文题目 | 【返回顶部】 |