|

范文编号:JX160 所有图纸,开题报告,文献综述,范文字数:7006.页数:30

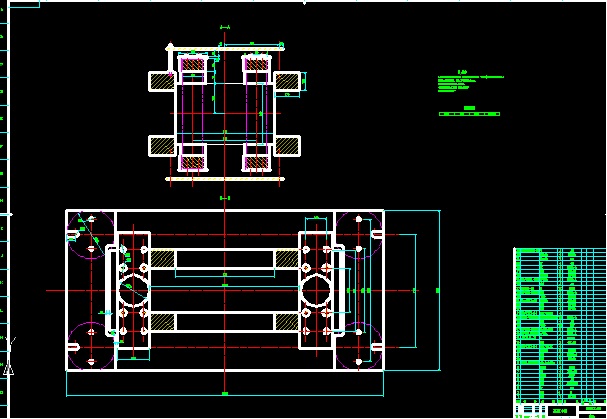

摘 要 机械压力机是最主要的锻压设备。它的工作原理是:电机带动皮带轮运转,经减速箱减速,然后带动轴转动,利用偏心齿轮使其带动冲头上下往复运动,达到冲压地目的。在设计过程中,首先查阅了有关高速压力机的资料,了解了高速压力机的工作原理及发展现状,然后根据高速压力机的设计方案要求,确定了该压力机的机械部分设计地最佳方案,并对选择的带轮、齿轮等零件进行了校核计算,最后用CAD绘图软件绘制了高速压力机的总装图和主要零部件图。

ABSTRACT Mechanical press is the most important forging equipment。Its working principle is: Motor driven pulley operation, After reduction box Slowdown,Then driven rotational axis,Use of eccentric gear,It led to-head under the reciprocating,To achieve the aim of stamping。In the process of the design, at first, Access to high-speed presses on the information,to understand the High-speed presses of its operation and the development present situation,then, according to the fuselage design proposal request,Determining the mechanical design of the press and the best option,And choose the pulley, gear and other parts were calculated Checking,Finally, using CAD software draw the assemble diagram and related part diagrams of the machine.

第一章绪论 ................................................................1 高速压力机相关范文 |

| 上一篇:关节型机器人腕部结构设计 | 下一篇:高空作业车液压系统设计 |

| 点击查看关于 高速压力机 的相关范文题目 | 【返回顶部】 |