|

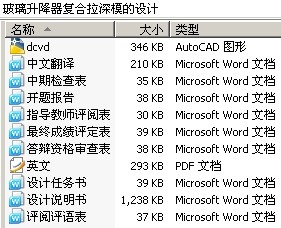

范文编号:JX1776 范文字数:20884,附CAD图纸,开题报告 ,外文翻译

摘 要 这份报告主要研究的是作为汽车零部件之一的活塞销的流动缺陷。在联合冷挤压制活塞销的工艺中,起皱就是一种流动缺陷,它是由死金属区引起的。玻璃升降器复合拉深模的设计-具有这种缺陷的部件带有很明显的外部特征,特征是被一微小而且厚的块状物嵌入材料中,这种缺陷对保证尺寸精度和降低材料损失是不利的,活塞销的这种缺陷对于其强度和疲劳寿命也有不利的影响。因此,在工艺设计的早期预测并防止这种缺陷是非常重要的。防止其产生的最好方法就是通过控制材料流动来限制或减少死金属区。有限元模拟分析方法被应用于流动缺陷研究分析当中,这份研究报告提出了通过去除死金属区防止产生流动缺陷的新工艺方法——有限元分析法。将有限元分析的结果与实验结果做比较,结果表明有限元分析的结果与实验结果相符合。 玻璃升降器复合拉深模的设计关键词:流动缺陷;活塞销钉;材料流动控制;前后双向冷挤压;死金属区;有限元分析 玻璃升降器复合拉深模的设计 ABSTRACT A flow defect of a piston-pin for automobile parts are investigated in this study. In the combined cold extrusion of a piston-pin, a lappingdefect, which is a kind of flow defect, appears by the dead metal zone. This defect is evident in products with a small thickness to be piercedand is detrimental to dimensional accuracy and decrease of material loss. The flow defect that occurs in the piston-pin has bad effects onthe strength and the fatigue life of the piston-pin. Therefore, it is important to predict and prevent the defect in the early stage of processdesign. The best method that can prevent the flow defect is removing or reducing dead metal zone through the control of material flow.Finite element simulations are applied to analyze the flow defect. This study proposes new processes which can prevent the flow defect byremoving the dead metal zone. Then the results are compared with the results of experiments for verification. These FE simulation results Keywords: Flow defect; Piston-pin; Material flow control; Forward–backward extrusion; Dead metal zone; FE simulation 玻璃升降器复合拉深模的设计 目 录 1 前言 5 玻璃升降器复合拉深模的设计相关范文 |

| 上一篇:风扇安装板的注射模具设计 | 下一篇:烤架手柄塑件注射模设计 |

| 点击查看关于 玻璃 升降 复合 设计 的相关范文题目 | 【返回顶部】 |